We combine proven standard products with customised, cost-optimised drive solutions – perfectly tailored to your requirements.

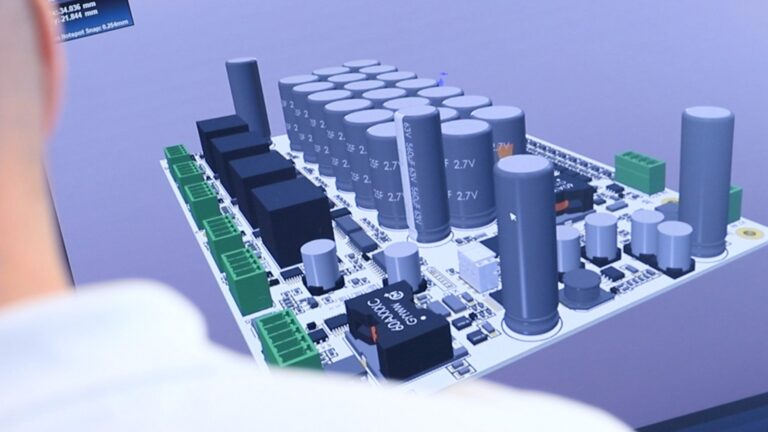

From evaluation, design and validation to product certification and support.

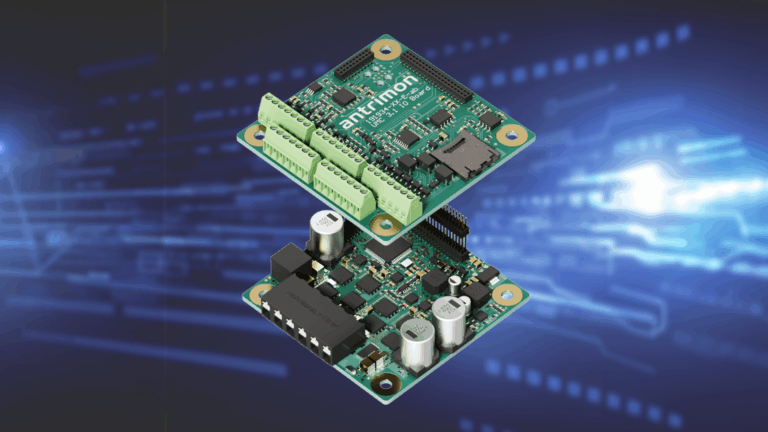

– Customised drive systems

– System integration and optimisation

– Prototypes and accompanying studies

Project example (full story available in the download area):

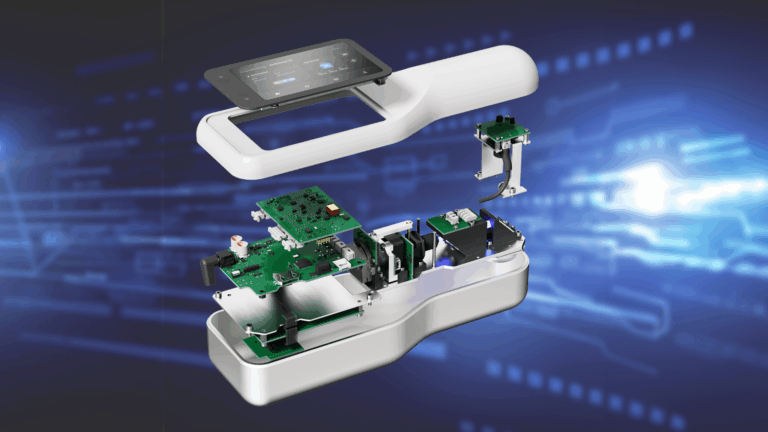

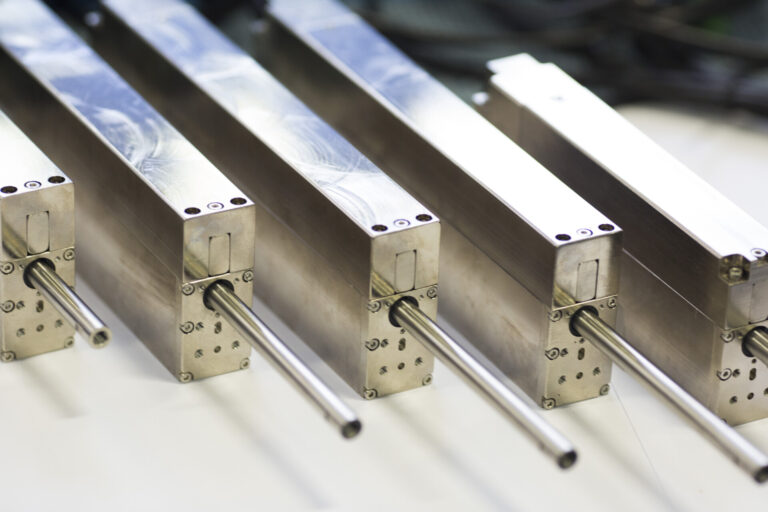

Antrimon developed a unique valve actuator for a global equipment manufacturer facing extreme operating conditions. The requirements were demanding: operation in ATEX and IECEx Zone 22, ambient temperatures from 5 to 50 °C, lifetime exceeding 10 million cycles, high continuous and acceleration torque at low speeds, minimal heat generation and maximum energy efficiency – all in a compact design with worldwide certifications (ATEX, IECEx, CE, UL). No such solution existed on the market.

Antrimon’s answer was a fully customised brushless outer-rotor motor combined with a two-stage planetary gearbox. The design focused on delivering maximum torque at the lowest speed, exceptional robustness and reliability. With a maintenance-free concept – no brushes, no oil changes – the actuator is built for continuous heavy-duty operation.

The entire process, from feasibility analysis and mechanical/electronic design to prototyping, extreme-condition validation, certification and series production, was handled in-house.

The result: significantly lower energy consumption compared to pneumatic systems, extended maintenance intervals, improved process safety and full global compliance. This solution gives the customer a clear competitive edge in international plant engineering. Antrimon is the only provider worldwide able to deliver such a certified solution economically from concept to series production.