The answer is provided by iST’s Moisture-in-Oil Sensor – a compact, digital RH/T module that accurately and continuously monitors the water content in oils and fuels.

Why is this important?

Over time, every lubricant ages: additives break down, contaminants creep in, and the oil’s ability to absorb water decreases. This can lead to costly breakdowns and unplanned downtime. The sensor does not simply measure the absolute water content – it measures the relative saturation level in % RH or water activity aw in %. This means you get a direct picture of the current oil quality and can react in good time.

Typical areas of application

The sensor is used wherever machines need to run reliably:

• Marine engines and gearboxes

• Commercial vehicles and rail vehicles

• Wind turbines and generators

• Drilling and paper machines

• Mobile oil filtration units

Designed for industrial use

Compact, robust, and easy to integrate, the sensor is built for harsh environments. It features a stainless-steel housing, digital interface for seamless system integration, and temperature-compensated, factory-calibrated measurement—ready for immediate use. Customized solutions, from mechanical integration to application-specific calibration, are also available.

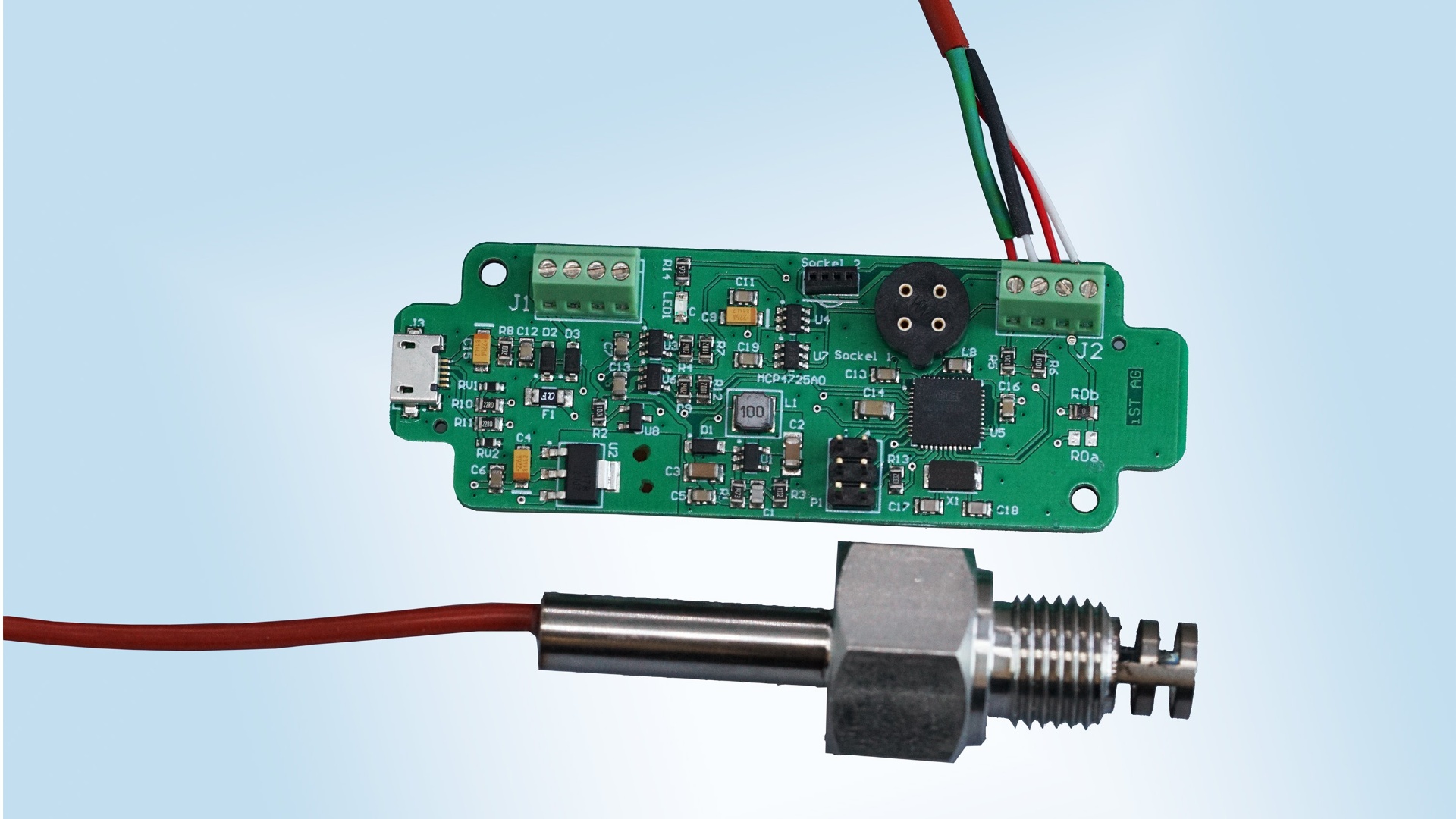

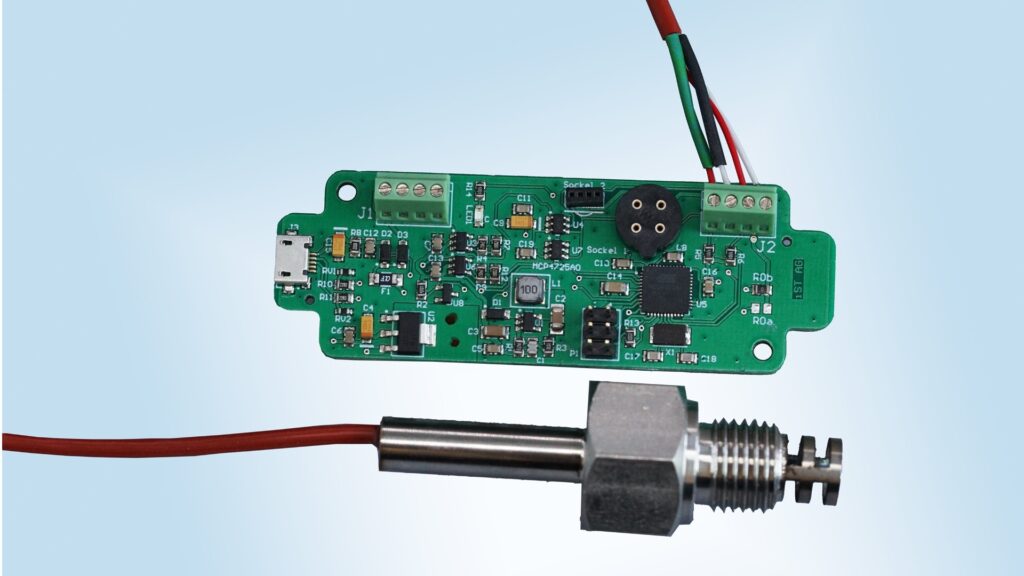

Evaluation kit – quick and easy testing

For fast evaluation and system tests, a complete evaluation kit is available. It includes a pre-mounted and calibrated sensor module, a test board with digital and analog outputs, USB connectivity, and compatibility with the Arduino IDE—ideal for lab work, prototypes, and initial application trials.