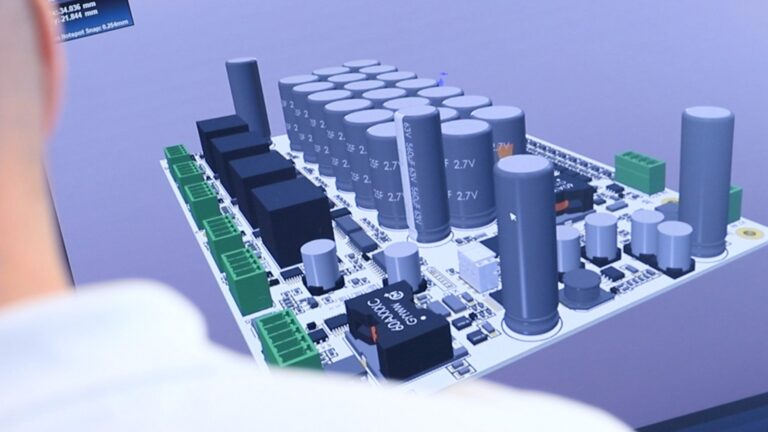

Ready-to-order drive controllers are inexpensive in the development phase, but include unnecessary functions and result in high unit prices in series production.

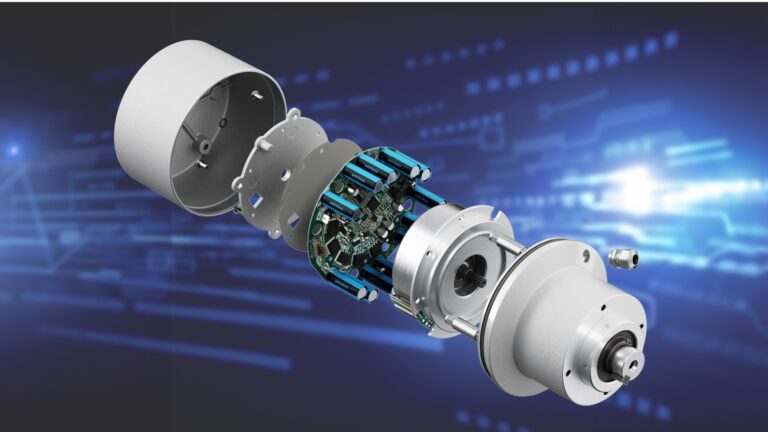

The flexible design of our motion control platform enables us to develop your individual solution tailored to your needs in the shortest possible time. You define the required specifications and we design your cost-optimised control system.

The advantages

– Cost reduction through tailor-made solutions

– Perfect adaptation to your own mechanics

– Increased innovation through rapid market introduction

– Competitive advantage in your industry

Project example (the full story can be found in the download area):

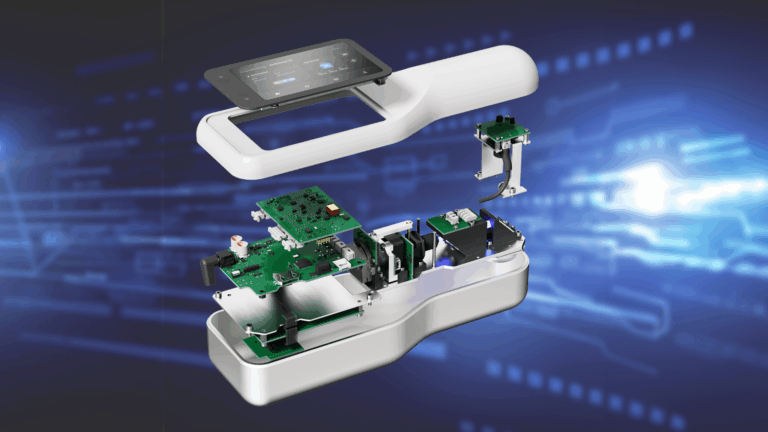

A new control module was developed to improve the cost-effectiveness and user-friendliness of an existing furniture moving system. It reduces manufacturing costs and significantly simplifies assembly and commissioning for the customer.

Integrated obstacle detection and absolute position

The motor control has integrated obstacle detection, eliminating the need for external sensors. A cost-effective SSI absolute encoder enables precise position detection. The system can reliably control up to three pieces of furniture simultaneously.

From prototype to series production

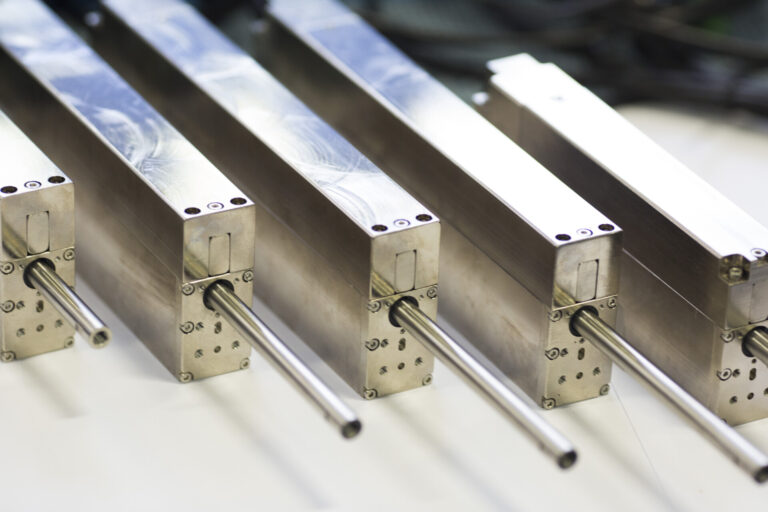

The project encompassed the entire development process – from the concept phase to prototypes to a solution ready for series production. The control unit, firmware, cabling and mechanical interfaces were completely redesigned. Suitable assembly and testing devices were created for series production.

Maximised customer benefit through system integration

-Significant cost reduction through the elimination of external sensors and simplified cabling

-Easy installation thanks to assembly-friendly design

-Modular design for flexible adaptation to different applications